QUALITY SCREENS FOR WATER INTAKE AND TREATMENT

Hendrick Screen offers various options — such as T-intakes, half intakes, drum screens and flat panels — all designed to be 316(b) compliant. Additionally, we have an engineering group dedicated to water intake and water treatment screens, thus ensuring you have the right screen for your application.

Hendrick Manufacturing is family-owned business established in 1876 where Hendrick screen started as a subsidiary in 1974. Hendrick Screen is the only US manufacturer offering wedge wire and profile bar. Hendrick stands as a quality manufacturer of engineered screens used in water, wastewater, reuse water, and fish hatchery intake structures, ponds and reservoirs. Used in multiple applications in over 35 countries Hendrick screens are manufactured of wedge wire technology and fabricated of various materials including stainless steel and copper nickel alloy.

Hendrick manufactures cost-effective water intake screens in stainless steel or copper-nickel. We produce intake screens in multiple sizes and configurations, including half intakes for shallow water conditions. A customizable Airburst system is available to op

timize performance and reduce cleaning costs. Our products are National Oceanic and Atmospheric Administration (NOAA) approved and 316(b) compliant.

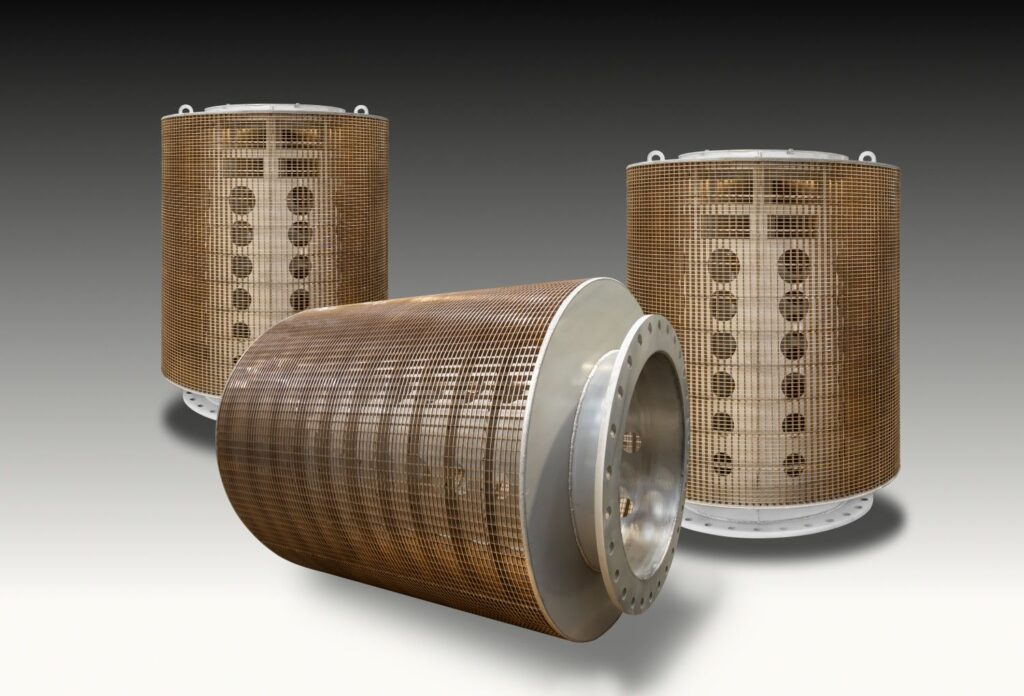

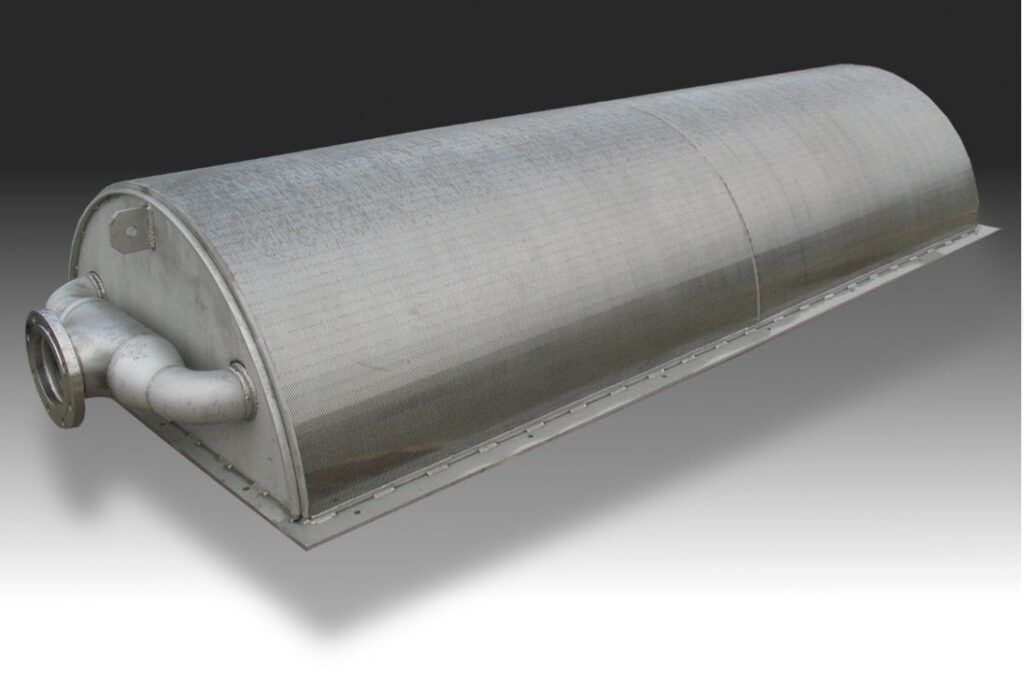

WATER INTAKE SCREEN CONFIGURATIONS

-

- T-intake screens

- Drum screens

- Flat panels

- Half-barrel intake screens *

- Optional Airburst Cleaning Systems

BENEFITS OF OUR WATER INTAKE FILTER SCREENS

-

- Passive — no moving parts

- Reduced operating costs

- Minimum clogging

- Maximum water flow

- Multiple designs accommodate deep to shallow depths

- Copper-nickel units available for anti-biofouling

- Compliant with Section 316(b) of the Clean Water Act

- Airburst cleaning system available

- Available in corrosion-resistant materials

PASSIVE WATER INTAKE SCREENS

Passive screening admits water through the intake point at a low, uniform velocity. Water passes through the water intake screen while debris and aquatic life remain in the water. Screens may be placed far from the shore for better water quality and lower concentrations of marine life and debris. With no moving parts, passive screens are reliable and easy to maintain.

WATER INTAKE FILTER SCREEN PRODUCTS

Hendrick manufactures T-intake screens with flexible, cost-effective designs. Flow modifiers maximize flow equalization, reduce head loss and minimize costs. For shallow-water applications, we offer a patented* half-barrel intake screen. This screen has the same flow characteristics as the T-intake screens, but it’s designed for shallow creeks and rivers where the full-size version won’t work.

Drum-style intake screens are ideal for use in lakes and reservoirs where there isn’t a linear flow pattern. They are also the best solution for installations where there are space restrictions that won’t allow a T-intake style screen to be utilized. Drum screens can be installed vertically or horizontally and can be customized based on a specific project’s intake requirements.

AIRBURST CLEANING SYSTEMS

Hendrick will work with you to design an Airburst System to deliver uninterrupted service to your water intake equipment. Each unit is fully customized to the specific needs of your water intake system and it's environment. Contact Hendrick today to discuss your needs.

WHY HENDRICK?

As experienced water intake screen suppliers, Hendrick Screen has more than four decades of experience and technical expertise in resistance-welded and Profile Bar screens. We offer screens in several configurations and materials, in a wide variety of sizes, shapes and precision openings. The goahttps://www.hendrickscreenco.com/l of our engineering team is to provide the most efficient screen design for your unique application. We’re always ready to help solve technical problems and assist in designing the most advantageous screen placement.

Visit Us At: Hendrick Screen Company